Seepage water treatment

We pursue clear goals with our sustainable environmental technology.

What is seepage water exactly?

Seepage water is a substance that unavoidably occurs when waste is landfilled – in particular due to precipitation such as rain and snow that seep into the landfill and absorb (hazardous) substances from the waste that are soluble in water.

Where does the seepage water go?

- The landfill's drainage system collects the seepage water

- Conveyance into the seepage-water storage basins

- The processing steps are gone through: sedimentation, homogenisation and ventilation

- Filtering out of the finest grain parts

- Further conveyance into the reverse osmosis plant

The seepage water at Ihlenberg is collected by an extensively constructed drainage system in the landfill and is conveyed via pipes into a 35,000 m³ seepage-water storage basin with floating cover. The seepage water stays in this collection basin and goes through the process steps of sedimentation, homogenization and ventilation.

Following the filtering out of the fine grain parts, the seepage water is subsequently conveyed into the reverse-osmosis plant. Permeat (pure water) and a concentrate that can be pumped (residual hazardous substances) result at the end of the separation process.

The pure water is almost the same quality as distilled water. That is why it also passes through the maturation pond and the biotope. Following several weeks in the pond, the cleaned water that is now free of hazardous substances is then tested and released into the natural outlet channel.

The principle of reverse osmosis is derived from nature; merely the direction of the osmotic flow is reversed and an additional pressure increase is triggered via membranes. Today, our leachate treatment facility is one of the most effective and largest in the whole of Europe. Our fully automatic, computer- controlled and pressure-staged reverse osmosis system works with up to 120bar and has a processing capacity of around 48 cubic meters per hour, currently enabling us to achieve a clean water recovery rate of 85% from the contaminated raw leachate.

How it works:

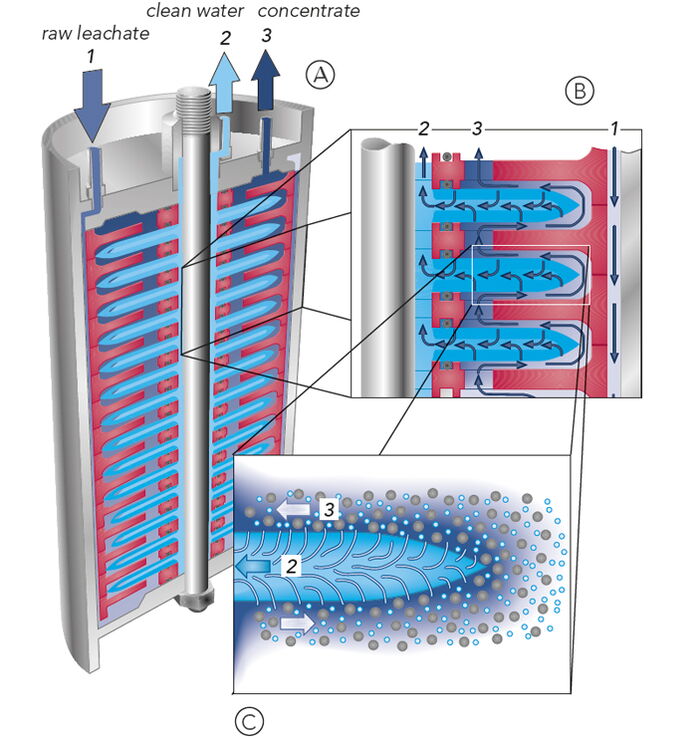

The raw leachate 1 is channelled into a separation process producing two mass flows - the clean water flow (permeate) 2 and the concentrate flow 3. The details are illustrated in the diagram:

A This is the inside of a module installed at our leachate treatment facility. In each pressure container, 150 hydraulic discs with 149 semi-permeable (half-porous) membranes are stacked. A high-pressure pump presses the raw leachate 1 into the module.

B The leachate flow path 1 indicated by the blue arrows overflows the membranes and clean water molecules 2 are pressed into the inner membrane cushions of each membrane. The detailed drawing (C) shows a schematic overview.

C The water molecules are collected inside the membrane cushion and flow alongside the clean water flow 2. The molecules with the polluting load concentrate on the outside of the membrane cushions and are discharge as the concentrate flow 3 to a storage tank prior to the proper and safe disposal.

The clean water 2 flows into the maturation ponds.