Sealing and covering systems

State of the art.

Geological conditions

The landfill site is located on an ice-age terminal moraine, that consists predominantly of layers that have been pushed against each other locally. Underneath is an extensive 30-metre-layer of till with clay. And underneath that is a further, similarly extensive layer of the same material. Altogether, this is an almost impenetrable barrier, and as a result, creates the ideal conditions for a safe landfill site.

But we do not rely solely on the geological conditions of course. Since 1987 we have complemented this principle with combination seals. A series of examinations carried out by the Landesamt für Umwelt, Naturschutz und Geologie (LUNG) Mecklenburg-Vorpommern (Ministry for the Environment, Natural Protection and Geology) has confirmed that no danger is posed to the environment and drinking water by the landfill in Ihlenberg.

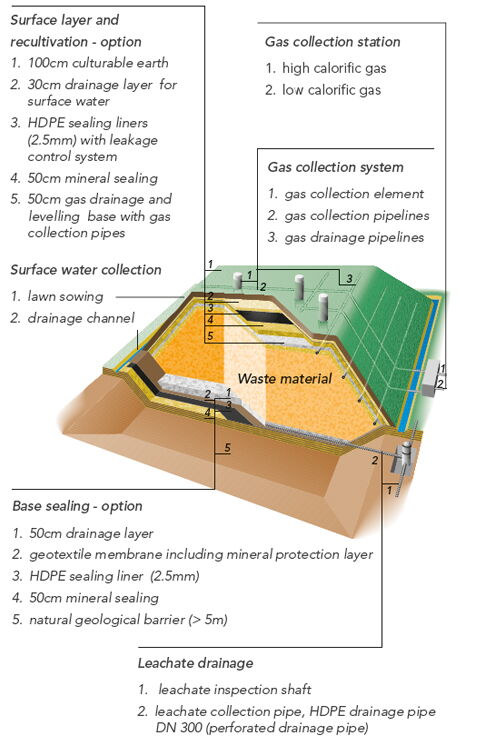

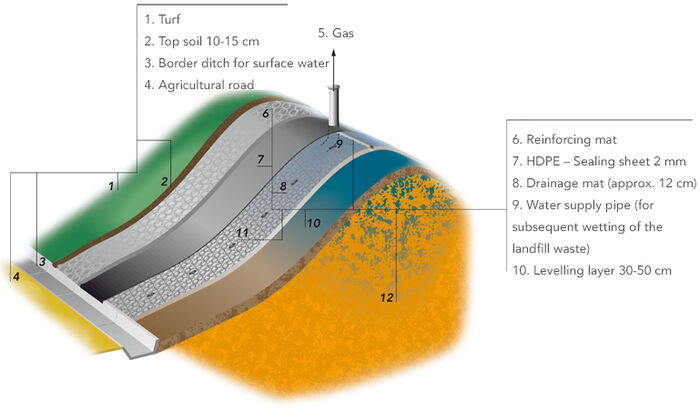

A further environmental protection measure that we use at the Ihlenberg site is the principle of combination sealings. We have illustrated the various components in the graphic on the right hand side. In addition to the already described basis sealing, we also focus on the surface sealing and the recultivation.

Basis sealing

Before the first waste may be brought to the landfill, the landfill basis must first be put in place in accordance with the statutory provisions.

Each new landfill section is first adjusted to a prescribed level using heavy machinery. The statutory provisions contained in the landfill directive state that the geological barrier needs to be at least 5 metres thick and needs to be constructed between the natural ground and the landfill sealing system.

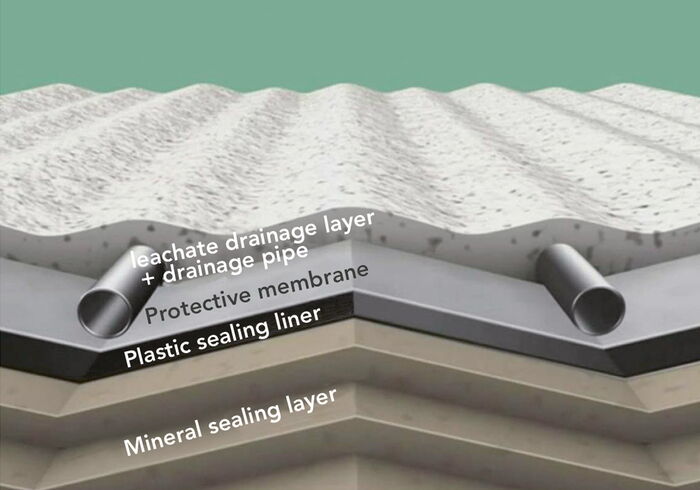

The mineral sealing layer that follows is evenly constructed in layers and compacted using a bulldozer, sheep’s foot roller and smooth roller. Following its completion, the mineral sealing layer will be 0.5 metres.

The laying of the drainage pipe on the sealing layer means that the water does not have the pressure in order to be able to penetrate the material. Nevertheless – as prescribed in the landfill directive – on top of the mineral sealing, a 2.5-millimetre-thick polyethylene sealing layer needs to be laid. The plastic sheets are securely welded together using a special mobile welding device. These sealing sheets have been in use for over 20 years and have proven themselves to be very reliable.

Basis sealing – roof-profile like construction in accordance with the latest technological standards (DepV)

- 50 cm seepage water drain layer with seepage water suction devices

- 15 cm mineral protective layer

- protective fleece

- 2.5 mm plastic sealing sheeting (HDPE)

- 50 cm mineral sealing

- Geological or technical barrier

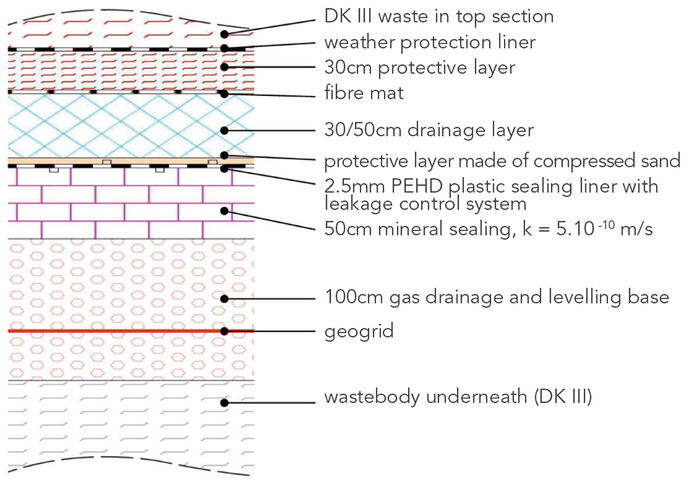

Intermediate cover

The comprehensive sealing measures put in place in those areas of the landfill in Ihlenberg that are already full ensure that no moisture in the form of rain or snow can reach the waste itself. The so-called infiltration is avoided. The precipitation flows off the intermediate cover and is gathered as surface water in the rainwater retention basin put in place for this purpose. From there the rain water is conveyed into the natural outlet channel after a safety sample has been taken. This helps to significantly reduce to amount of seepage water which is created. This means that the storage volume as well as the capacity of the cleaning plant can be reduced.

A further positive effect that we were able to achieve in Ihlenberg with the landfill-cover measures taken was to significantly reduce the smell generated by the landfill gas. On a covered surface area of 578,000 m² (status: December 2015), the gas migration through the surface of the landfill is effectively stopped in the areas of the landfill that have already been filled. In this way, the landfill gas is conveyed into the many gas-storage wells using a vacuum without any losses, and into the gas accumulation station via a permanent pipe system.

All-in-all – a building measure with a quadruple benefit

- Avoiding gas migration/odour emissions

- Reducing the capacity of the cleaning plant

- Reducing the volume of seepage water storage

- Minimising the amount of seepage water occurring

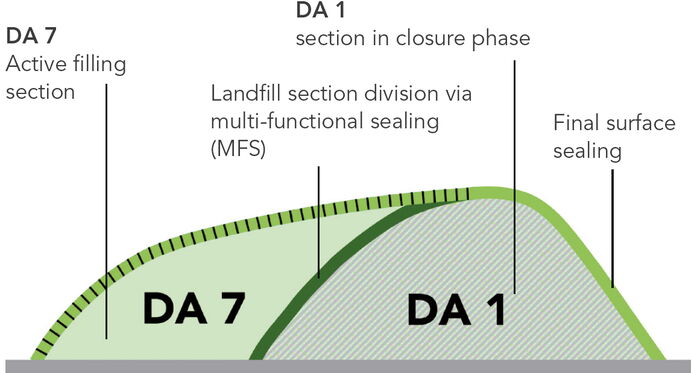

Multifunctional Sealing

The goal pursued with the construction measure "Multifunctional Sealing (MFS)" is

- the structural separation of sections of the landfill currently in the closing-down phase (summarised as DA 1) from the current filling area (Da 7),

- the manufacture of final surface sealings (SS) for the partial areas of the landfill sections currently in the closing-down phase,

- as well as complementing the basis sealing for a partial area of the still active DA 7.

This means that the individual MFS functions are sufficiently described.

The erection of the multifunctional sealing represents a technically challenging construction process and which will mark, on the one hand, the start of the final closing down process of the so-called old area of the landfill in Ihlenberg, and on the other hand, the remaining capacity to take waste of the sections of the landfill still in operation.

This means that Northern Germany will continue to have sufficient waste-disposal capacity for Landfill Class III waste into the future that corresponds with the very latest state of the art standards.